Reliability Prediction Analyses

What is Reliability Prediction Analyses (RPA)?

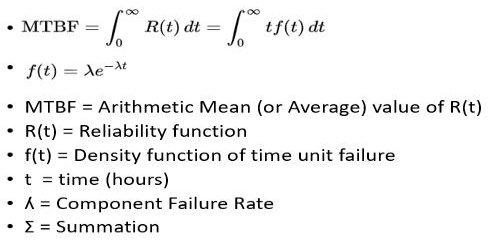

RPA is the quantitative evaluation of a product’s Reliability performance. It entails Failure Rate (ʎ) and Mean Time Between Failure (MTBF) estimations.

Definitions:

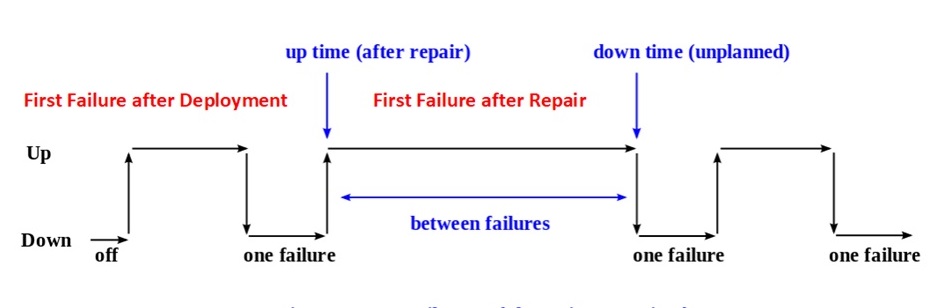

- MTBF is calculated as the arithmetic mean (average) time between failures of a

system. - MTBF unit is depicted in hours.

In general, MTBF is the "up-time" between two failure states of a repairable system during operation as outlined here:

Equations:

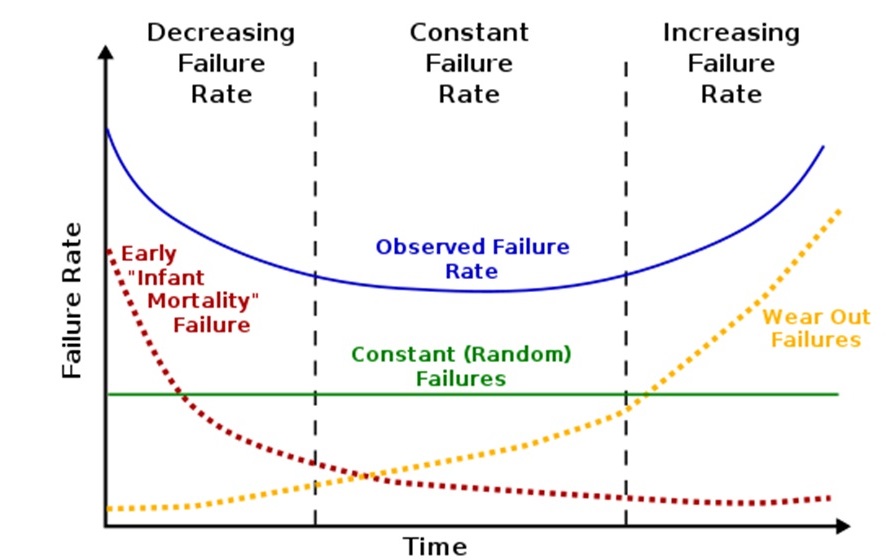

Reliability Graph (Bathtub Curve):

Notes:

- Constant failure rate (ʎ) is utilized to estimate MTBF.

- Environmental Stress Screening (ESS) addresses infant mortality failures during manufacturing process. ESS eliminates manufacturing defects.

- Weibull Analyses predicts Wear Out failures.

Weibull Analyses:

A statistical analysis that predicts the probabilities of infant mortality and wear out

failures.

Dansob Weibull Analyses emphasizes on wear out failures only.

Objective:

The primary objective of Weibull Analyses is to espouse and improve product reliability by introducing Scheduled Maintenance Interval (SMI).

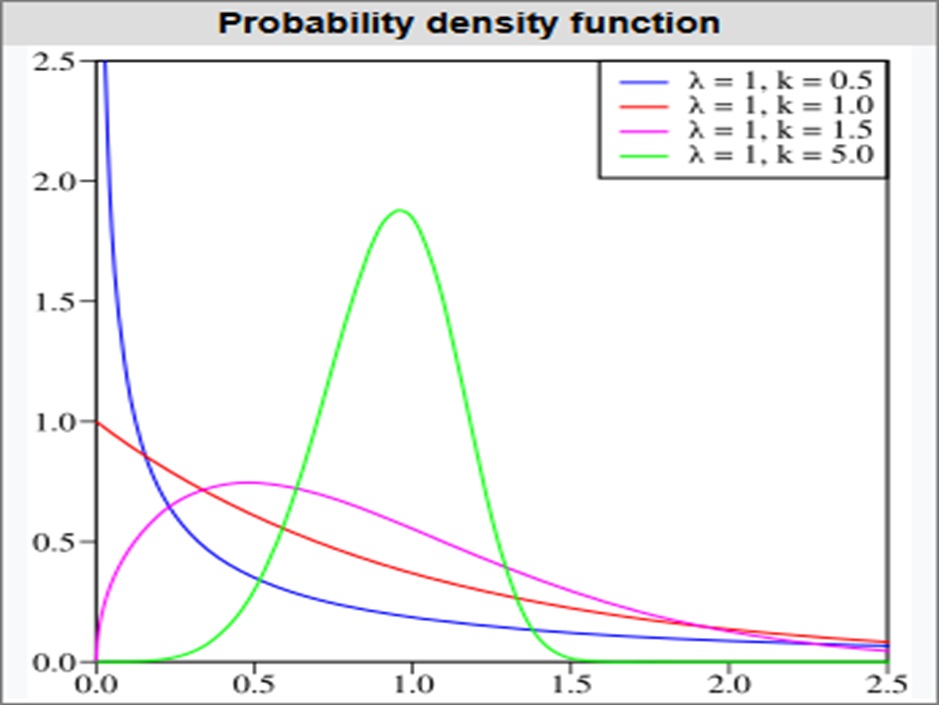

SMI is established by converting an exponential probability density function into a constant probability density function.

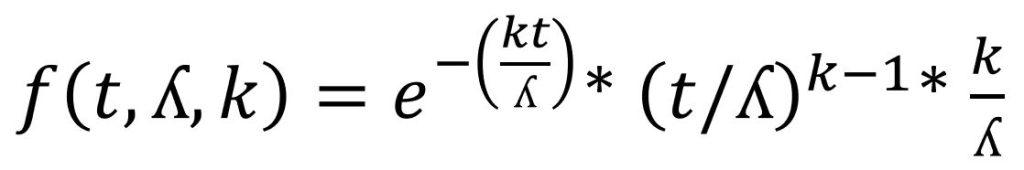

Equations:

F(t, ʎ, k) = Probability Density Function

k = Shape Parameter

ʎ = Failure Rate (per hour)

t = time (in hours)

Graph: