Failure Mode and Effect Analyses

Failure Mode and Effect Analyses (FMEA) / Failure Mode, Effect and Criticality Analyses (FMECA)

Definitions:

FMEA/FMECA is a systematic method of analyzing a product design or system to attain the following objectives:

- To identify single point failure modes within the product design or system that would cause safety-critical effects and undermine operational safety.

- To provide risk mitigation recommendations for such identified safety-critical failure modes.

FMEAs and FMECAs are performed at the component and functional levels.

Component level FMEAs and FMECAs are fastidious, comprehensive and highly desirable.

Pertinent to FMECA:

Failure modes and effect descriptions are categorized into hazard severity classifications.

Hazard Severity Classifications includes the following: Catastrophic, Hazardous (or Critical), Major, Minor and No Effect.

Hazard Severity Classifications are considered System Safety Assessment elements.

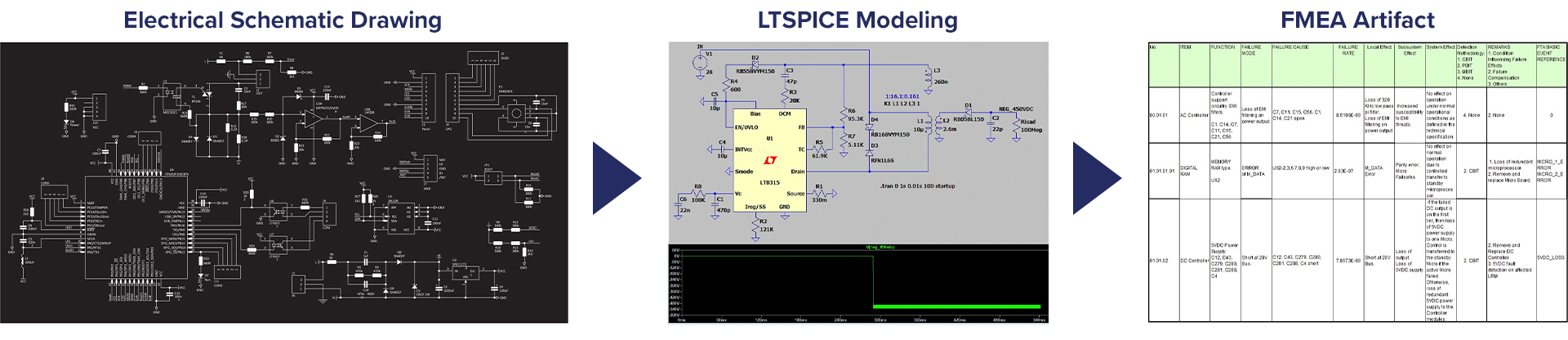

FMEA/FMECA Process Flow