Mechanical Engineering

Mechanical Design & Analysis

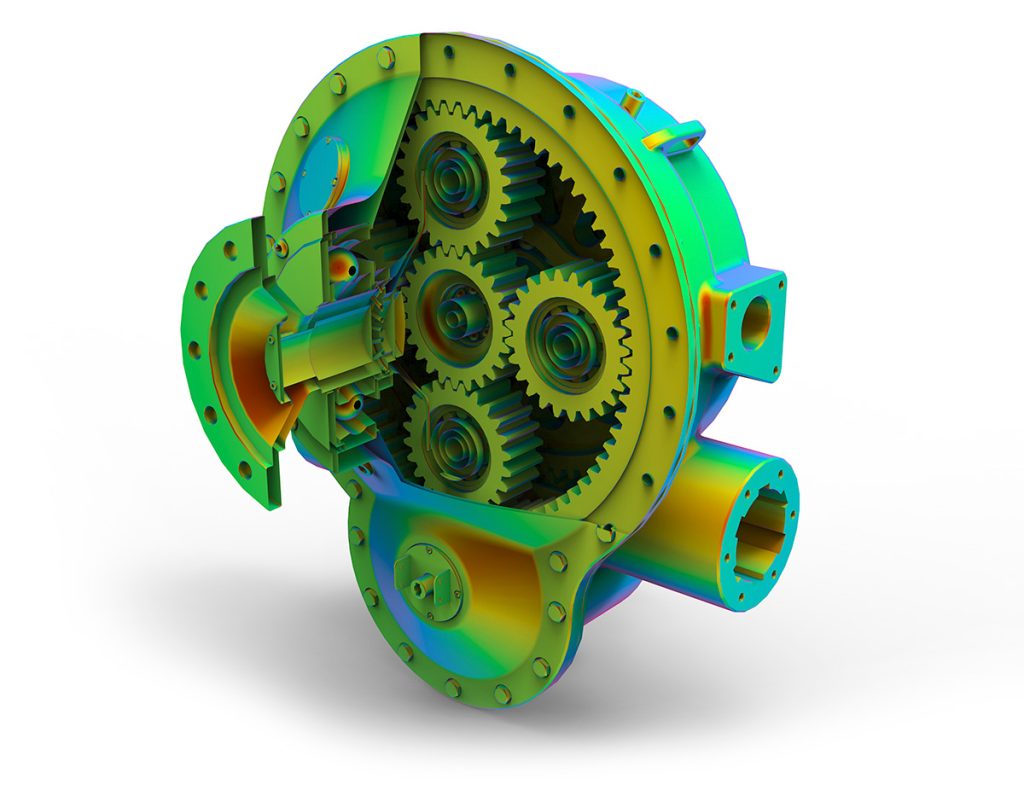

Mechanical Design & Analysis is the cornerstone of engineering, focusing on transforming concepts into practical, functional products. This process involves the development of detailed 3D models and drawings using CAD (Computer-Aided Design) tools, ensuring each component is precisely engineered to meet specific performance criteria. Engineers analyze various factors such as load-bearing capacities, material properties and manufacturing constraints to optimize the design for real-world conditions. The goal is to create robust, efficient and cost-effective products while minimizing risks such as failure or inefficiency.

Analysis is equally critical in mechanical design, as it ensures that designs can withstand the forces and environmental conditions they will encounter during operation. Engineers perform simulations and tests to predict how components will behave under various loads, including mechanical stress, thermal fluctuations and dynamic forces. These analyses help refine the design, ensuring safety, durability and compliance with industry standards.

Custom Product Design

At Dansob we are able to create tailored engineering solutions that meet specific client requirements, from concept to final product. The process begins with a thorough understanding of the client’s goals, operational needs and design constraints.

Design for Manufacturability (DFM) ensures products are easy and cost-effective to produce by addressing manufacturing considerations early in the design process. This involves selecting appropriate materials, simplifying assemblies and optimizing parts to streamline production, reduce costs and ensure scalability.

Design Optimization and Iteration focuses on refining the product through testing and analysis. By developing prototypes and making iterative improvements, engineers enhance performance, durability and efficiency, ensuring the final product meets both functional and manufacturing requirements.

Additional Mechanical Engineering Services

Thermal Analysis (Conduction, Convection, Radiation, Steady State & Transient Thermal)

Thermal analysis ensures optimal heat management in mechanical systems by evaluating heat transfer through conduction, convection and radiation. We analyze both steady-state and transient thermal conditions to ensure systems maintain thermal stability during operation, preventing overheating and ensuring longevity.

Finite Element Analysis (Static, Vibration, Thermal & CFD)

Finite Element Analysis (FEA) simulates how designs perform under different conditions. From static and vibration analysis to thermal and fluid flow (CFD) simulations, FEA helps predict stress, deformation and heat transfer, ensuring your designs meet strength and performance requirements.

Structural Analysis (Stress, Strain, Deformation & Fatigue)

Structural analysis evaluates how materials and components withstand stress, strain and deformation over time. By predicting fatigue and failure points, we ensure that structures can handle operational loads and extend product lifespan.

Dynamics and Vibration (Modal, Harmonic, Transient & Random)

Dynamics and vibration analysis helps predict how components respond to time-varying forces. Modal, harmonic, transient and random vibration studies ensure that systems operate safely and efficiently, avoiding issues like resonance and excessive vibration.

Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics (CFD) simulates the behavior of fluids and gases in and around mechanical systems. By optimizing fluid flow and heat transfer, CFD improves system efficiency in applications ranging from aerodynamics to cooling systems.

Tooling, Fixtures and Work Holding Design

Custom tooling, fixtures and work holding solutions are essential for efficient, precise manufacturing processes. We design tools that improve production quality, reduce cycle times and ensure parts are securely and accurately held during machining and assembly.

Technical Reviews and Documentation

Thorough technical reviews and detailed documentation ensure designs meet performance standards and regulatory requirements. We provide comprehensive reports, including CAD drawings, testing data and user manuals, to guide product development and manufacturing.

Materials and Manufacturing Methods Support

Selecting the right materials and manufacturing methods is critical to product success. We offer expert guidance on material selection based on strength, durability and cost. We also recommend the best manufacturing techniques to ensure efficient production.

Systems Engineering

Systems engineering ensures that all components of a project work together seamlessly. By integrating mechanical, electrical and software systems, we manage the complexity of large-scale projects to deliver optimized and reliable solutions.

Reverse Engineering

Reverse engineering allows us to recreate or improve existing products when original designs are unavailable. Using advanced tools, we replicate parts, identify design flaws and enhance performance, making it possible to modernize or repair legacy systems.

Get in Touch with the Experts

Contact us today to learn how our mechanical engineering solutions can help your business.