Fuel use is one of the highest costs in air travel. It also affects the air we breathe. When planes burn more fuel, they release more smoke into the sky. This is why fuel efficiency matters more than ever.

At DANSOB, we work to solve this problem with smart and tested methods. Our aerospace engineering solutions help planes use less fuel without losing power or safety. We design, test, and improve systems that bring real change. Our aircraft engineering services support airlines, makers, and defense teams in many ways.

This guide explains how fuel use can be improved with modern aerospace work. It also shows how our team supports this goal with skill and care.

Why Fuel Efficiency Matters in Modern Aviation?

Fuel is the heart of every flight. A small rise in fuel use can lead to high costs. Over time, this affects profit, ticket price, and air health.

Better fuel use helps in many ways:

- It cuts travel costs

- It lowers the smoke in the air

- It increases flight range.

- It supports clean goals

- It boosts flight value

Air firms now want smart ways to save fuel. This is where engineering plays a key role. Our aerospace engineering solutions focus on this need.

How Aerospace Engineering Improves Fuel Use?

Fuel saving is not done by one change alone. It needs many small gains. Each part of a plane plays a role. Our aircraft engineering services work on all these parts with care and skill.

1. Light Weight Aircraft Design

A heavy plane burns more fuel. A light plane uses less. This rule guides many design plans today.

At DANSOB, we help reduce weight by:

- Using light metal and a strong mix of parts

- Removing extra design load

- Improving frame balance

- Using smart part fit

This change may look small. But over many flights, the fuel savings are big.

2. Better Aerodynamic Shape

Air push is a major cause of fuel loss. When a plane fights the air, it burns more fuel.

We improve aircraft shape by:

- Smoothing the wing surface

- Adjusting wing tips

- Improving body flow

- Reducing drag points

These changes help the plane move with ease. This lowers fuel burn at cruise speed.

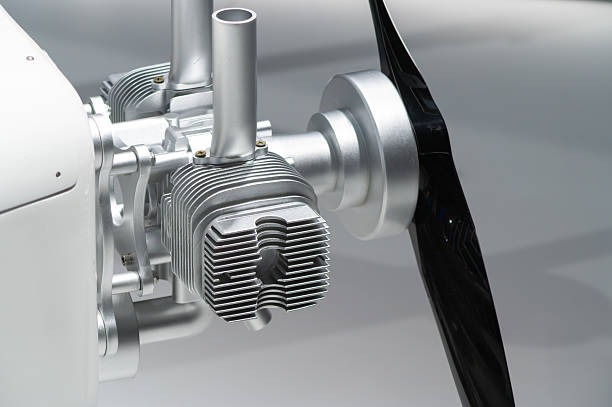

3. Engine System Optimization

The engine is the main fuel user. Even a small gain in engine work can save a lot of fuel.

Through our aerospace engineering solutions, we help to:

- Improve air intake flow

- Cut heat waste

- Improve burn cycle

- Reduce idle fuel use

We also support engine test and data check to find loss points.

4. Smart Electrical System Design

Old power systems waste fuel. New smart systems reduce the engine load.

Our aircraft engineering services include:

- Smart power flow design

- Low loss unit setup

- Energy use balance

- Reduced system drag

These changes help the engine focus only on flight power.

5. Landing Gear and Structural Drag Control

The landing gear adds drag and weight. We help improve it.

We work on:

- Clean gear shape

- Fast retract systems

- Smooth surface link

- Better lock design

This helps lower drag during climb and cruise.

Role of Digital Testing in Fuel Saving

Real flight tests are costly. Digital tests save time and money. They also help improve accuracy.

At DANSOB, we use:

- Digital flow test

- Load stress test

- Heat loss check

- Drag flow test

These tests help us fix fuel loss before real flight use.

Maintenance Engineering for Long-Term Fuel Gains

Fuel efficiency does not stop after design. Over time, wear and tear raise fuel use again.

Our aircraft engineering services support:

- Predictive maintenance

- Wear check planning

- Part life tracking

- Failure risk control

This keeps the plane in the best shape for long fuel gain.

System Safety Engineering and Fuel Control

Unsafe systems waste fuel and raise risk. Safety and fuel savings work together.

Our aerospace engineering solutions include:

- System failure check

- Risk data mapping

- Fault loop control

- Safe fuel feed design

This protects both the fuel and the flight crew.

Industries We Support With These Solutions

Our fuel-saving work supports many flight sectors:

- Civil aircraft

- Space systems

- Defense aircraft

- Air mobility systems

- Test flight units

Each system needs a custom plan. We design based on the task needs.

How DANSOB Stands Apart?

Many firms offer design help. But not all focus on smart fuel gain with safety and cost control together.

At DANSOB, we offer:

- Deep aerospace skill

- High test accuracy

- Custom design work

- System-level thinking

- End-to-end support

Our aerospace engineering solutions are not just plans. They are working systems that save fuel in real use.

Key Benefits of Our Fuel Efficiency Solutions

When you work with us, you gain:

- Lower fuel cost

- Longer flight range

- Better system life

- Less air smoke

- Higher aircraft value

These gains help both profit and planet.

Future of Fuel Efficiency in Aviation

The future of flight is lean, clean, and smart. Fuel saving will grow through:

- New fuel mix

- Hybrid engines

- Smart AI flight paths

- Better material science

Our aircraft engineering services already support this future. We help clients prepare for coming needs.

Why Choose DANSOB for Aerospace Engineering Solutions?

We work as your long-term partner. We do not sell plans alone. We build working answers.

With DANSOB, you get:

- Expert teams

- Proven test tools

- Clear workflow

- Full support cycles

- On-time results

We turn design into real savings.

FAQs

1. What are aerospace engineering solutions for fuel efficiency?

These are design and system methods used to lower fuel use. They include weight cut, air flow control, engine optimization, and smart power systems. At DANSOB, we apply these methods based on aircraft type and mission need.

2. How do aircraft engineering services reduce fuel cost?

Our aircraft engineering services find fuel loss points in design and system flow. We then remove waste through shape change, load cut, and system balance. This lowers fuel burn per flight.

3. Can old aircraft also gain from fuel efficiency upgrades?

Yes. Older planes can gain a lot. Through system upgrades, surface smooth work, and engine support, we can reduce fuel loss without a full redesign.

4. Do fuel efficiency upgrades affect flight safety?

No. At DANSOB, safety comes first. Our aerospace engineering solutions balance fuel savings with full safety rules. All changes pass strict system checks.

5. How long does a fuel efficiency improvement project take?

Time depends on project size. Some system upgrades take weeks. Full design changes take more time. We always share a clear timeline before work starts.

6. Does DANSOB offer full engineering support?

Yes. We offer full aircraft engineering services. This includes design, analysis, testing, safety, and long-term support.

7. Which industries can use your fuel efficiency solutions?

Civil aviation, defense, space, air mobility, and OEM units can use our aerospace engineering solutions.

Final Words

Fuel efficiency is not just a cost goal. It is a global need. Every saved drop of fuel helps airlines grow and keeps the sky clean.

At DANSOB, we take this goal seriously. Our aerospace engineering solutions and aircraft engineering services work together to make planes smarter, lighter, and more efficient.

We do not follow trends. We build systems that last.

If your goal is to save fuel, extend range, and protect the future of flight, DANSOB is ready to support your mission.