Maintainability Engineering

Our Approach to Maintainability

Maintainability Engineering focuses on designing, operating, and managing systems in a way that maximizes ease of maintenance. By incorporating the principles of maintainability from the beginning, businesses can achieve reduced downtime, faster repairs, and extended operational lifespans for their equipment and systems.

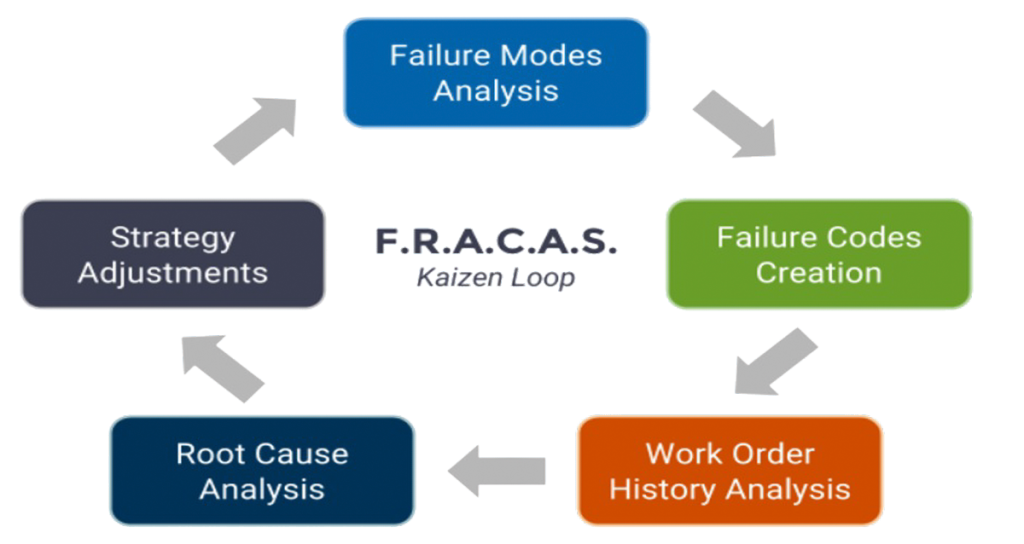

Utilizing The FRACAS process, we help design systems with maintainability in mind. Our approach ensures that systems are easy to service, repair, and maintain, which leads to increased reliability and lower overall costs.

Benefits of Maintainability Engineering

Implementing Maintainability Engineering ensures that our customers maintenance processes are streamlined, efficient, and cost-effective. By prioritizing ease of maintenance from the design phase onward, Dansob clients can achieve significant operational advantages and long-term savings.

Some of the benefits of Maintainability Engineering includes:

- Reduced Downtime: Less time is spent repairing systems, which means more uptime and productivity.

- Lower Maintenance Costs: By designing systems for easy maintenance, fewer resources are needed for repairs and replacements.

- Improved Reliability: Preventative maintenance programs ensure that equipment operates reliably, reducing the risk of unexpected failures.

- Extended Equipment Lifespan: Well-maintained systems last longer, protecting our customers investment.

- Enhanced Safety: By ensuring equipment is easy to maintain, Dansob clients reduce the risk of accidents or failures during repair work.

The FRACAS Method

Failure Reporting and Corrective Action System (FRACAS) is a closed loop failure reporting and tracking system. Dansob utilizes FRACAS to monitor and improve its customers Product Field Reliability performance. We accomplish this assertion by utilizing the FRACAS data to engender Strategic Product Reliability Improvement Initiatives (SPRII) and attain Product Reliability improvement objectives.

Dansob Maintainability Engineering objective entails the alignment of FRACAS and Reliability artifacts. This would provide valued feedback input to enhance SPRII and help our customers make better informed decisions pertinent to product maintenance.

FRACAS elements involves:

• Product Field Return Descriptions

• Root Cause Investigations and Findings

• Corrective Action Implementations

• Statistical Analyses

• Reliability Improvement Recommendations

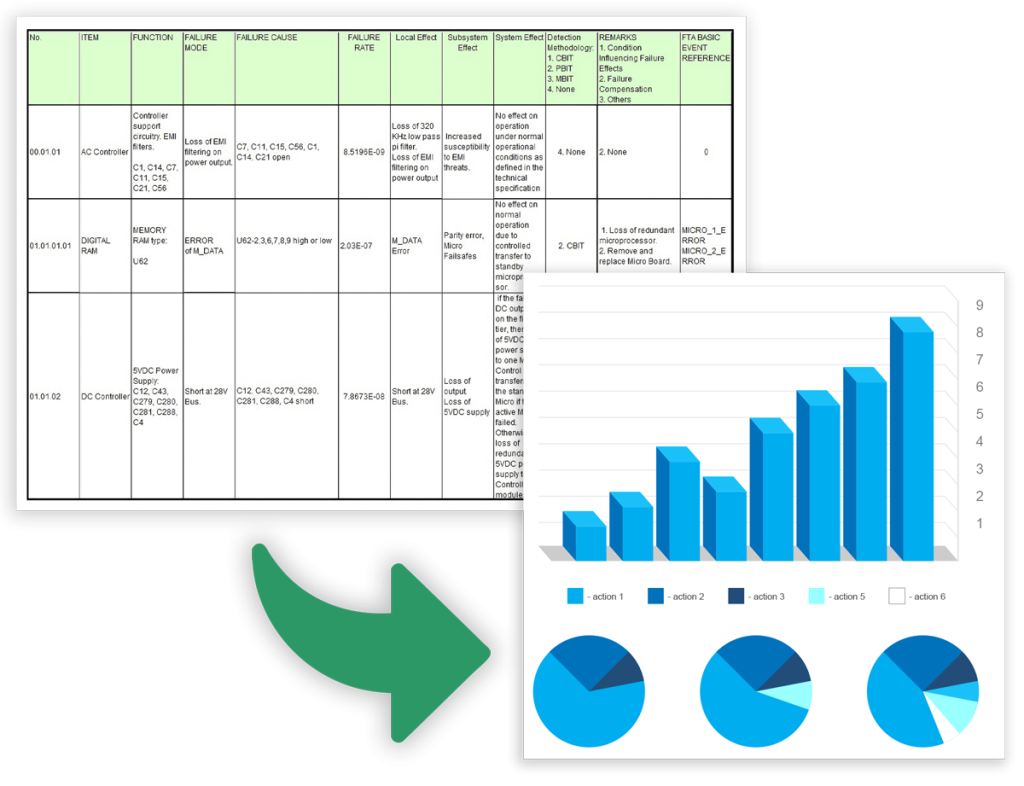

FRACAS elements are reflected in a spreadsheet analyses artifacts.

FRACAS artifacts are depicted in a documentation report.

FRACAS reports are developed on a periodic basis predicated on the customers’ requirements or requests.

Frequently Asked Questions

What is the primary goal of Maintainability Engineering?

Maintainability Engineering ensures that systems are easy to maintain, reducing downtime and improving reliability while minimizing costs over the system's lifecycle.

How do you measure maintainability?

We use various metrics like Mean Time to Repair (MTTR) and Mean Time Between Failures (MTBF) to assess and improve maintainability.

How can we integrate maintainability in the design phase?

Incorporating design for maintainability early ensures that systems are built with accessibility and ease of maintenance in mind, saving costs and time in the long run.

Ready to Optimize Your Systems?

Contact us today to learn how our Maintainability Engineering solutions can improve your operational efficiency and reduce costs. Let us help your business achieve its engineering goals.