Electrical Engineering

Creating Efficient Electrical Systems

At Dansob, we specialize in creating a safe and efficient electrical system for diverse applications in various industries (examples include: aerospace, automotive, rolling stock, utilities, medical, semiconductor devices and industrial plants).

We Meet the Following Standards:

- RS-103

- DO-160

- DO-254

- DO-178

- MIL-STD- 461

Power & Control Electronics Solutions

We offer advanced Power & Control Electronics Solutions designed to meet the unique challenges of modern industries. Whether you need precision control for manufacturing or reliable power distribution, our solutions are built for efficiency, scalability, and safety.

- Power Electronics: Efficient management of electrical energy with systems like inverters, converters, and uninterrupted power supply (UPS) for stable power flow.

- Control Systems: Custom-built automation solutions integrating PLCs, sensors, and actuators for industrial process control.

- Mission Critical Design: focuses on creating systems and solutions that are essential for the reliable operation of critical tasks, ensuring safety, efficiency, and resilience under all conditions.

- Magnetic Design: optimizing magnetic systems and components to efficiently control and utilize magnetic fields in various applications like motors, transformers, and sensors.

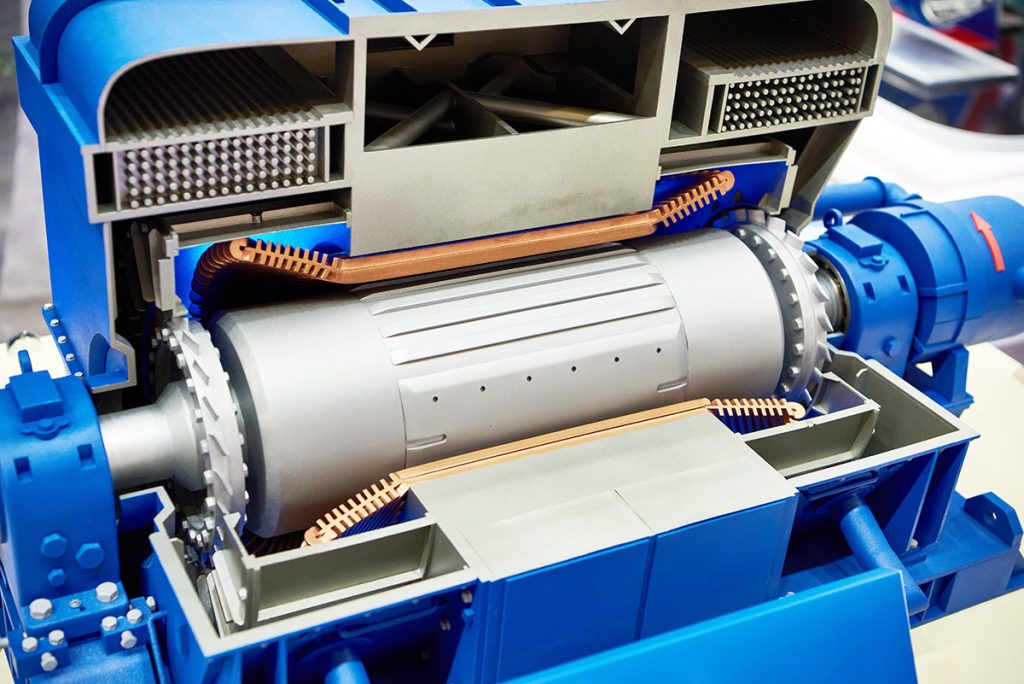

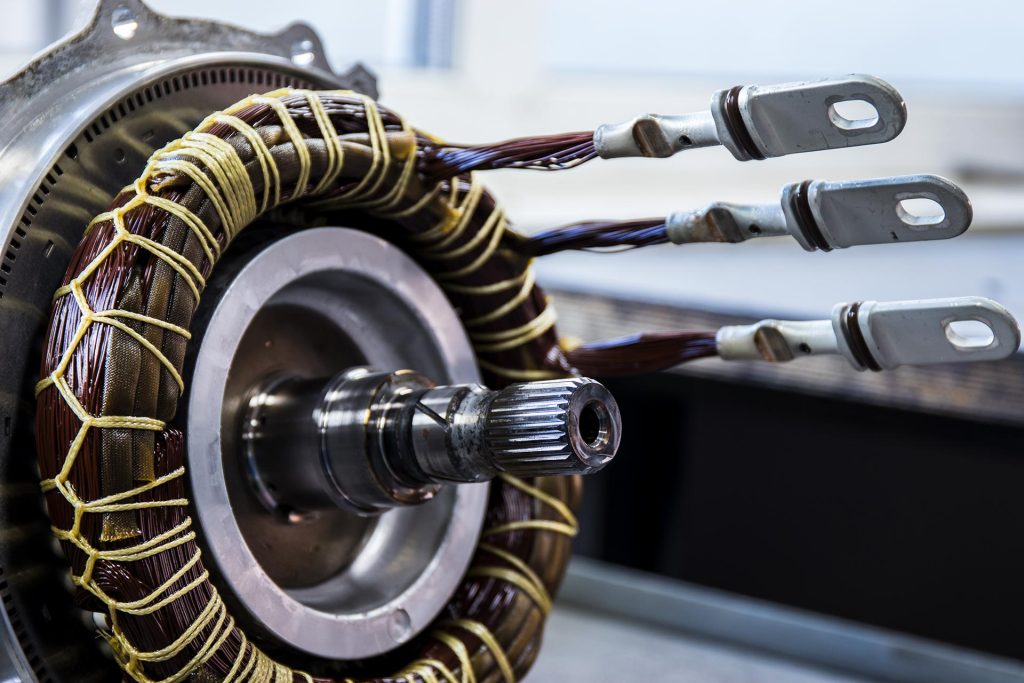

Electric Machine Solutions

Leveraging its wealth of experience and technical expertise, Dansob has engineered Electric Machines (EM) capable of operating up to 1KV and 40,000 RPM

Dansob is committed to ensuring the timely delivery and optimal performance of its EM designs.

Our EM Type Expertise Involves :

- Brushless Wound Field Generator

- Limited Angle Torque (LAT) Motor

- Permanent Magnet (Surface Mounted & Embedded)

- Induction (Single & Multiphase)

- Synchronous Reluctance (With & Without PM Assisted)

- Brushed DC (PM, Series, Parallel & Compound)

Dansob EM solutions are customized in conformance with our customers requirements. Let us design the EM solutions that best meet your needs.

Our Specialties

We specialize in delivering a complete suite of Electrical Engineering Solutions, ensuring high performance and innovation across every stage of development:

Custom Design

We create tailored magnetic designs to address unique challenges, focusing on optimizing functionality and efficiency.

Development & Prototyping

From concept to physical prototypes, we develop and test magnetic systems to refine performance before full-scale production.

Bearing Selection & Design

Our expertise in bearing design considers the critical impact of unbalanced magnetic forces on the rotor, ensuring smoother, longer-lasting operation.

Thermal Analysis & Management

We conduct detailed thermal analyses to manage heat within systems, preventing performance degradation and ensuring reliability.

System Optimization

We enhance system performance through careful analysis and optimization, ensuring minimal energy loss and improved efficiency.

Design for Manufacturability

Our designs are optimized for ease of manufacturing, balancing quality with cost-effective production processes.

Manufacturing Support

We provide hands-on support during production, ensuring seamless manufacturing transitions with expert guidance on materials and processes.

Product Qualification

Comprehensive testing and qualification services to certify that your products meet regulatory and performance standards.

Reviews & Documentation

We offer thorough technical reviews and precise documentation to support regulatory compliance and design validation.

Reverse Engineering

Our reverse engineering services allow us to improve existing designs or recreate obsolete components for better performance and functionality.

Each of these specialties ensures that our Electrical systems are efficient, reliable, and ready for real-world applications, no matter how complex the requirements.

Ready to Discuss Your Project?

Contact us today to learn how our Electrical Engineering solutions can help your business.