Reliability Engineering Solutions

Ensuring Dependable Performance

Reliability Engineering is the cornerstone of designing, maintaining, and operating systems that consistently perform as intended. From complex machinery to high-tech devices, reliability ensures that your systems operate efficiently with minimal downtime, helping you save costs, improve safety and maintain customer satisfaction.

At Dansob, we specialize in providing comprehensive Reliability Engineering solutions to ensure your products and systems deliver optimal performance throughout their life cycle.

What is Reliability?

Reliability refers to the probability that a system or component will perform its intended function under specific conditions for a designated period of time without failure. It is a crucial metric in ensuring that products and systems operate dependably and safely.

Key Metrics

- MTBF (Mean Time Between Failures): The average time between failures for repairable systems.

- MTTF (Mean Time To Failure): The average time until a non-repairable component fails.

- Availability: The probability that a system is operational when needed.

- Failure Rate: The frequency of system failures, typically expressed as failures per unit of time.

Why is it Important?

Reliability engineering ensures that systems are designed, maintained, and operated in a way that maximizes their dependability, which has significant benefits:

- Operate Safely: Preventing critical failures in industries like aerospace, defense, and healthcare, where failures can lead to severe consequences such as injury or loss of life.

- Perform Efficiently: Maximizing system uptime and minimizing downtime, leading to greater operational efficiency and effectiveness.

- Reduce Costs: Lowering costs associated with repairs, replacements, and unplanned downtime through better design and preventive maintenance.

- Extend Lifespan: Improving the durability and longevity of products and systems by addressing potential failure points early in the design and maintenance process.

Reliability Engineering Tools and Techniques

Reliability engineers utilize several tools and techniques to ensure system reliability:

- Failure Mode and Effects Analysis (FMEA): A systematic approach to identify potential failure modes, their causes, and effects, and prioritize actions to mitigate failures.

- Reliability Block Diagrams (RBD): Visual models that represent how components within a system contribute to overall reliability.

- Weibull Analysis: A statistical method used to model and predict the time to failure of products.

- Spreadsheet: A computer application for computation, organization, analysis and storage of Reliability Data in tabular form.

- LTSPICE: A software application utilized for electronic circuit drawings, simulations and modeling.

Our Reliability Engineering Process Flow

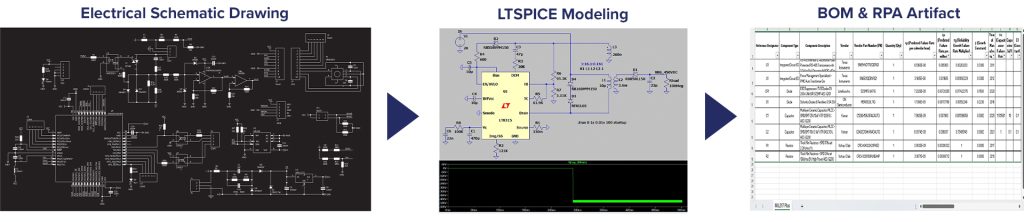

RPA Process

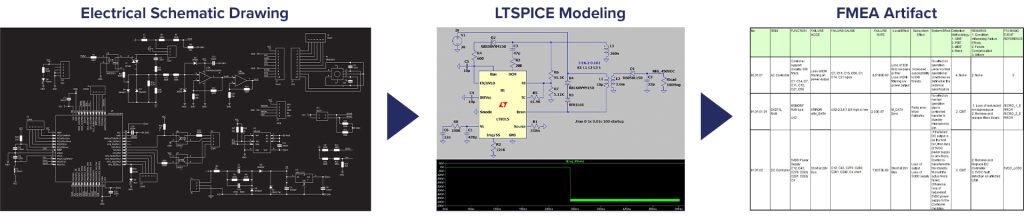

FMEA & FMECA Process

Dansob utilizes the Bills of Material (BOM), Electrical Schematic Drawing and LTSPICE Modeling to produce the Reliability Prediction Analyses (RPA), Failure Mode and Effect Analyses (FMEA) and Failure Mode Effect and Criticality Analyses (FMECA) artifacts.

Reliability Artifacts

Reliability Artifacts are sets of Reliability Contents deliverables that Dansob provides to its customers in compliance with the customer’s requirement specifications. Dansob Reliability Artifacts entails:

Reliability Prediction Analyses (RPA)

Failure Mode and Effect Analyses (FMEAs)

Reliability Testing

Industry Standards

Reliability Objectives

Identify & Mitigate

Help our customers to identify and mitigate safety-critical single point failure risks within their Product Designs, Systems or Processes.

Informed Recommendations

Provide informed recommendations that supports Product Reliability improvements.

Reliability Improvements

Facilitate Product Reliability improvements that aid our clients in attaining optimal product performance.

Cost effective & optimal solutions

Espouse the production of cost effective and optimal solutions.

Meeting Specifications

Ensures our Product Reliability key metric attribute (MTBF or MTTF) meets our customers Reliability Objective Requirement Specifications.